Contents:

Contents:

1. Engine Identification

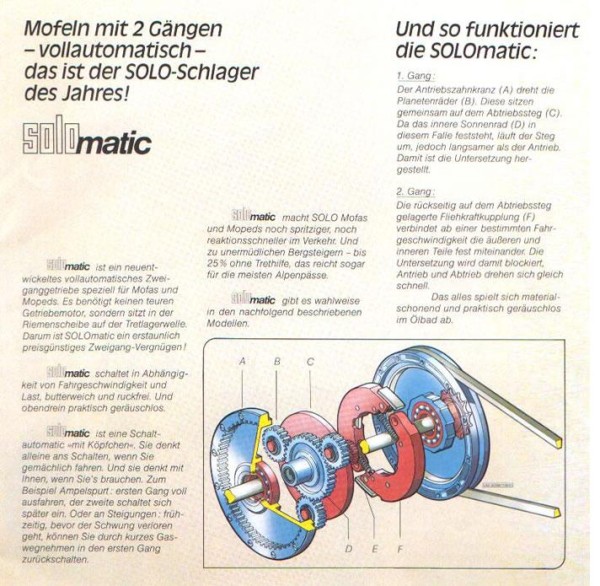

2. Transmission Identification

3. SOLOmatic Two Speed

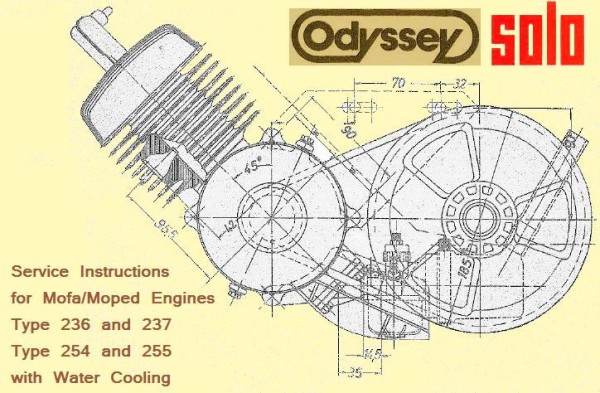

4. Engine Specifications

5. Odyssey Type 254, 255

6. Columbia Type 255

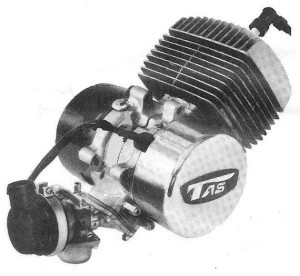

7. Tas BE48 Type 237

8. 1990’s Solo

Solo Engines are made in Germany by SOLO Kleinmotoren GmbH, Postfach 600152, D 71050 Sindelfingen, Germany. Solo made mostly small agricultural motors, chain saws, sprayers, etc. The name is from the revolutionary backpack portable sprayer for pesticides in 1951. The “Solo” could be used by a single person for the first time, whereas in the past pesticide sprayers required a heavy stationary motor pump and several assistants to handle the long hose.

1. Solo Engine Identification

Solo 236 and 237 engines have no coolant plug above spark plug

Solo 254 and 255 engines have a coolant plug above spark plug

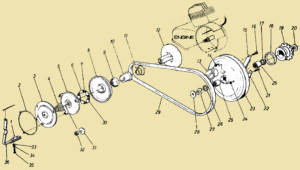

2. Solo Transmission Identification

Solo Regular (1-speed) has no pulley screws, disk clutch with start lever

Solo 2-Speed has 12 pulley screws, a shoe clutch with auto start

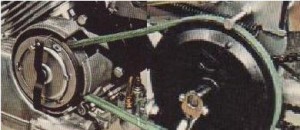

How to identify a 1 or 2 speed: There are two types of belt-drive transmissions, 1 speed and 2 speed. The one-speed (ein-gang) “regular” transmission has a solid rear pulley, with no screws around the edge. The two-speed (zwei-gang) transmission has a rear pulley with planetary gears and a second speed auto clutch inside, with 12 screws around the edge. The presence or absence of pulley screws is the best way to tell a 1-speed from a 2-speed, from a few yards away. If the clutch cover is off, the presence or absence of the manual starting clutch lever is another way to tell. 1-speeds have it but 2-speeds do not.

3. SOLOmatic Two Speed (Zweigang)

The amazing Solomatic Zweigang rear pulley changes speeds in a step, with planetary gears and an auto clutch inside the pulley, in an oil bath. That is way different from a much simpler variable V-belt pulley that gets wider or narrower continuously, according to centrifugal weights. So the Solomatic is a “true” 2-speed, not a CVT.

More info about the Solo 2-speed: “Home Alone with Mopeds” has an excellent blog about the Odyssey 40/2-2 two-speed belt drive moped. An all original fresh condition bike is photographed and explained, inside and out. Included are pictures of the planetary gears, the second speed auto clutch, and the “secret” switch that allows backing up without turning the engine over backwards. Click here for a beautiful adventure and lesson on German engineering: http://homealonemopeds.blogspot.com/2013/10/solo-odyssey-402-with-stock-solomatic.html

4. Solo Engine Specifications

The specifications below are from the Odyssey Service Manual, 1977 edition, and from direct measurement.

| SOLO ENGINE | Type 236 | Type 237 | Type 254 | Type 255 |

| ================= | ================= | ============== | ============== | ============== |

| bore x stroke | 38 x 43 mm | same | same | same |

| displacement | 48.7 cc | same | same | same |

| compression ratio | 8.3 : 1 | 7.5 : 1 | 8.3 : 1 | 10.0 : 1 |

| horsepower | 1.45 hp | 2.1 hp | 1.75 hp | 2.6 hp |

| max torque | 2.3 ft-lb | 2.2 ft-lb | 2.4 ft-lb | 2.7 ft-lb |

| CYLINDER | alum. w/steel sleeve | same | same | same |

| cooling | air cooled only | air cooled only | air + water | air + water |

| transfer ports | (2) left and right | (2) left and right | (3) left, right, rear | (3) left, right, rear |

| cylinder size, new | 38.00 (1.4961") | same | same | same |

| PISTON | Mahle 19 x 10 x 22 | same | same | same |

| piston size at skirt, new | 37.96 (1.4945") | same | same | same |

| piston clearance range | 0.04-0.06 (.0016-.0024") | same | same | same |

| piston rings (2) type | 38.0 x 1.5 side-pin | same | same | same |

| ring gap range | 0.02-0.05 (.008-.0020") | same | same | same |

| top-edge-to-pin | 19 mm | same | same | same |

| piston pin | 10 mm x 32 | same | same | same |

| pin-to-bottom-skirt | 22 mm | same | same | same |

| needle bearing cage | 10 x 14 x 13 | same | same | same |

| CRANKSHAFT | 5-piece type | same | same | same |

| needle bearing cage | 14 x 18 x 10 | same | same | same |

| right (magneto) nut | M10-1.0 (Ø90 flywheel) M8-1.0 (Ø80 flywheel) | same | same | same |

| left (clutch) nut | M10-1.0, 17 hex | same | same | same |

| L+R ball bearings | 15 x 35 x 11 #6202 | same | same | same |

| right (mag) seal | 15 x 25 x 5 | 15 x 25 x 5 | 15 x 35 x 7 | 15 x 35 x 7 |

| left (clutch) seal | 15 x 25 x 5 | 15 x 25 x 5 | 26 x 35 x 7 | 26 x 35 x 7 |

| left seal function | seals case to shaft | seals case to shaft | seals case to clutch | seals case to clutch |

| clutch bearing seal | 15 x 21 x 3 | 15 x 21 x 3 | 15 x 21 x 3 | 15 x 21 x 3 |

| clutch seal function | oil only, no pressure | oil only, no pressure | seals clutch to shaft | seals clutch to shaft |

| CLUTCH | single plate dry | same | same | same |

| running clutch | centrifugal automatic | same | same | same |

| friction plate thickness | 3.8 mm (0.150") | same | same | same |

| clutch grab speed | 2600 rpm | 2850 rpm | 2600 rpm | 2850 rpm |

| starting clutch | manual hand lever | same | same | same |

| needle bearing sleeve | 15 x 21 x 16 | same | same | same |

| PULLEY and BELT | Z-profile 10 x 6 | same | same | same |

| needle bearing sleeve | 16 x 22 x 22 | same | same | same |

| GENERATOR (Euro) | Bosch 0212-005-011 80mm clockwise M22-1.5 puller | same | same | same |

| lighting coil (Euro) | 6 volt 17 watt | same | same | same |

| GENERATOR (USA) | Bosch 0212-124-039 90mm clockwise M26-1.5 puller | same | same | same |

| head light & horn coil | 6V 22W, yellow wire | same | same | same |

| tail light coil | 6V 5W, grey wire | same | same | same |

| stop light coil | 6V 10W, green & grn/blk | same | same | same |

| IGNITION | magneto, blue wire | same | same | same |

| points gap | 0.35-0.45 (.014-.018") | same | same | same |

| ignition timing | 2.4 mm BTDC | 2.4 mm BTDC | 3.0 mm BTDC | 3.0 mm BTDC |

| spark plug | NGK B5HS | NGK B5HS | NGK B6HS | NGK B6HS |

| spark plug gap | 0.5 mm (0.020") | same | same | same |

| CARBURETOR | Bing 1/10/112 | same | same | same |

| venturi size | 10 mm | same | same | same |

| main jet | Bing 3.5mm #58 | same | same | same |

| choke system | cable operated | same | same | same |

Notes:

Clutch Seal: The pressure seal for the clutch side on the 254/255 is not just one seal, like normally. It is two seals, the outer one 26x35x7 seals case-to-clutch, and the inner one 15x21x3 seals clutch-to-shaft. This is the Laura clutch seal/bearing design, similar to Batavus. Instead of being separate in it’s own grease, the clutch needle bearing is bathed in the two stroke oil and gasoline. The benefit is it never needs to be greased. The drawback is the crankcase pressure has another place to possibly leak, both fresh air inwards, and fuel/air mist outwards.

5. Solo 254 and 255

5. Solo 254 and 255

with disk clutch (Regular), or shoe clutch (2-speed)

1976-78 Odyssey (US models)

model (speed) engine transmission

32/1-R (20 mph) Solo 254, Regular

32/1-2 (20 mph) Solo 254, 2-speed

40/1-R (25 mph) Solo 255, Regular

40/1-2 (25 mph) Solo 255, 2-speed

40/2-R (30 mph) Solo 255, Regular

40/2-2 (30 mph) Solo 255, 2-speed

6. Solo 255

6. Solo 255

Solo “Odyssey” with Columbia-made clutch and no coolant

Solo 255 with Colombia “belt clutch”. The sides of the belt are the friction surface. No clutch shoes, no friction plate or disk.

1979-80 Columbia (US models)

model (speed) engine transmission

2240 (25 mph) Solo 255, Columbia, soft tail, long seat

2241 (20 mph) Solo 255, Columbia, soft tail, long seat

2242 (30 mph) Solo 255, Columbia, soft tail, long seat

2250 (25 mph) Solo 255, Columbia, hard tail, solo seat

2251 (20 mph) Solo 255, Columbia, hard tail, solo seat

2252 (30 mph) Solo 255, Columbia, hard tail, solo seat

1979-80 Ward and Western Flyer (US models)

model (speed) engine transmission

8240 (25 mph) Solo 255, Columbia, soft tail, long seat

8241 (20 mph) Solo 255, Columbia, soft tail, long seat

8242 (30 mph) Solo 255, Columbia, soft tail, long seat

8250 (25 mph) Solo 255, Columbia, hard tail, solo seat

8251 (20 mph) Solo 255, Columbia, hard tail, solo seat

8252 (30 mph) Solo 255, Columbia, hard tail, solo seat

1988-93 KKM Mopet (US models)

model (speed) engine transmission

340 (25 mph) Solo 255, Columbia, soft tail, solo seat

341 (20 mph) Solo 255, Columbia, soft tail, solo seat

342 (30 mph) Solo 255, Columbia, soft tail, solo seat

How the automatic clutch works: The engine is idling and the belt is stationary. The pulley sides are spinning, but the pulley center is not, because it is on a needle bearing. As the engine begins to rev up, the weights #6 fly out from centrifugal force. They force the outer pulley half #8 inward, causing the sides of the belt to rub on the spinning pulley sides. The bike begins to move forward. As the speed increases the weights fly out more and more. When the revs are high enough, the weights are fully out, and the belt is not slipping, or almost not slipping. When the bike slows down, the spring #7 pulls the weights back in, and the slipping process reverses.

How the starter clutch works: A manual start lever on the handlebar pulls a cable, that pulls a start lever #36 against the clutch. It moves a plates #3 and #5 inward. That forces the outer pulley half #8 to rub hard against the belt. Then moving the bike forward, either by pushing or pedaling, causes the engine to turn over, and hopefully start up (if other things are working). When the start lever is released, moving the bike forward has no effect on the engine.

More clutch info: The Colombia “belt clutch” has a needle bearing in the front pulley that allows the belt to be stationary while the engine crankshaft is spinning at idle speeds. Those needle bearings often go out, and bind. Then the bike won’t stay idling unless the rear wheel is allowed to rotate at around 5 mph. The thin needle bearing needs to be greasy, inside, but the belt that goes around it needs to be not greasy.

Columbia (Solo) front pulley needle bearing

TR0414P520518 made by Koyo

Another problem is high friction. As explained above, the sides of the belt are the friction surface. The trouble is, the design causes a lot of friction, so you have to push or pedal really hard. The excess friction is from the belt rubbing the pulley sides the wrong way. The belt only moves in a circular motion for half way around, then it moves across the pulley, not with it. Some people are not strong enough to get it started.

Another problem is slippage. The sides of the belt always slip a little, but they slip a lot when greasy. Then you have to pull very hard with your left hand on the start lever. The hard squeeze required eventually leads to the starter pieces wearing out fast. Once that happens, some people end up wrapping a rope around the flywheel to use as a pull starter. De-greasing the belt, and applying sticky spray for squealing belts, should help it to not need such a strong squeeze on the hand lever.

7. Solo 237 clone

7. Solo 237 clone

with Tanaka-made “belt” clutch (no plate or shoes)

8. 1990’s Models

8. 1990’s Models

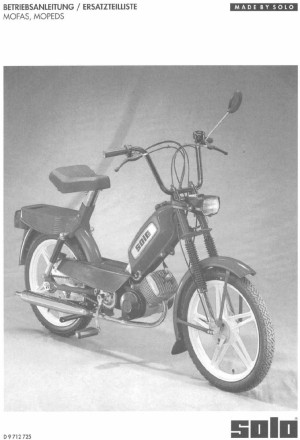

1994 Solo 712 or 713 (Euro model) Owners Manual and Parts List

The 70’s bike, 20 years later.

Modern gel seat, modern controls, no more chrome, aluminum wheels that resist bending.

Same engine, frame, exhaust, fork, etc.

Same loose ball and cone wheel bearings.

“Euro version” floor boards, lights, and bell.

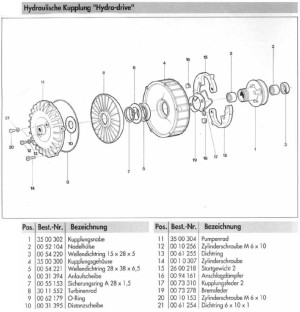

Solo 1990’s Hydraulic Clutch “Hydro-Drive”