Generic Cables Cable Parts

Service Info

Welcome. This cable section is for control cables, that slide back and forth, not speedometer cables, that rotate. For speedometer cables, see Parts/Frame/Speedometer.

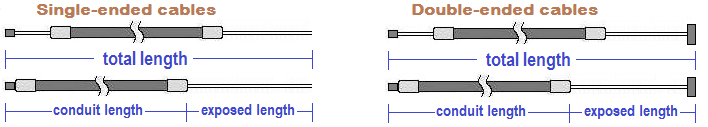

Single or Double Ended: Some control cable inner wires have two ends, and some have only one. The “end” is a round piece if metal, usually soldered onto the braided steel wire. When a cable inner wire has only one end, it can be removed from the conduit (or sleeve or housing). When a cable inner wire has a ball of lead at both ends, then it is permanently trapped and cannot be removed without cutting one end off.

Lubing Cables: Old cables become sticky from deteriorated oil and corrosion. A few drops of fresh thin oil is often all the cable needs to work good again, after a long period of sitting. Apply a few drops of oil or synthetic lubricant (preferably Tri Flow) onto the upper exposed inner wire so that it runs downhill into the cable. The bike is leaned over so that cable entrance is going down. The oil takes a few minutes to flow down the wire. Straighten out any kinks in the cable. Also lube the throttle, especially sliding block kinds, and the levers, where the lever pivots, and where the cable pivots.

Cutting cables: The preferred tool is called a diagonal cutting pliers. It must be fairly new and sharp to cut braided steel cable inner wires and coiled steel cable outer conduits. Most of the inexpensive kinds do not stay sharp long.

Configuring cables: A single ended “universal” cable is configured, or made into, a double ended “specific” cable. Any cutting of the sleeve, adding stop pieces, adapters or adjusters is done first. Then the cable is installed on the bike. Lastly, the top end piece is installed in the correct location on the wire. The wire strands are bent into an umbrella, and soldered. This is often necessary when ready-made cables are not available.